Bordelmachine SMT Schleifstein - KBoL 2010-200

MACH-ID 7373| Merk: | SMT Schleifstein |

| Type: | KBoL 2010-200 |

| Besturing: | Playback |

| Bouwjaar: | 2002 |

- CNC Controll MIPC Q Playback with GAP control

- Large package TOP rolls 5 units

- Large package forming & pressure rolls 5 units

- Loading attachment

- Unloading attachment

- Under power out put 6 units

- Controllable forming roll drive

- Hydraulic displacement drive

- Clamping device without hole

- Basket bottem

- Knocker bottom

- Pressure vessel bottom

- Boiler bottoms

- Flat floor

- Plate base

- diffuser bottom

- Tank bottom

- Tank bottom

- Radar reflectors

- Engine parts

- Dispense air

- Silo hoppers

- Cooker hoods

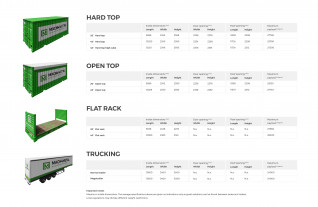

- Container parts

- Hemispheres

Specificaties

Afmetingen (Schatting)

Belangrijk: De informatie op deze pagina is naar beste vermogen en overtuiging verkregen en waar nodig verkregen van de fabrikanten.De nauwkeurigheid kan niet worden gegarandeerd maar de informatie wordt te goeder trouw gegeven. Dienovereenkomstig vormt het geen vertegenwoordiging of contractuele voorwaarden.We raden u aan om alle essentiële details te controleren!

Head manufacturing lines for precise production of tank

and vessel heads

Step-by-step, partial forming (dishing) of

the round to form a dished disk,on a hydraulic dishing unit, consisting of a press with

manipulator.

Bending (flanging) the edge of the dished

disk to guarantee that there is no clear-cut

to the cylindric tank,on a flanging machine.

We are the pioneers for these production

procedures and have been dealing with the

improvement of the production lines and

processes for decades:

• increase of the repetitive accuracy

• decrease of production times

• reduction of personnel costs

• reduction of production material costs

• increase of production quality

• automation of production

• conversion of operator know-how into

control know-how of the machine

As outstanding characteristics of our machines only two examples are highlighted here:

PLAYBACK-Control for the dishing units.

Automatic setting to a new round diamter

in less than 3 minutes.

Electronic Gap Control for the flanging

machine. Automatic and material-friendly

running along the forming roll contour with

a specified distance to the pressure roll.

Apart from using the latest controls you can

rely on the familiar Schleifstein-quality. We

also guarantee the well-known longevity

and high availability of Schleifstein-machines by our worldwide service.

Specify your application to us and we will

find an appropriate sol

Recent bekeken machines

Terug naar overzicht