Deze machine is verkocht

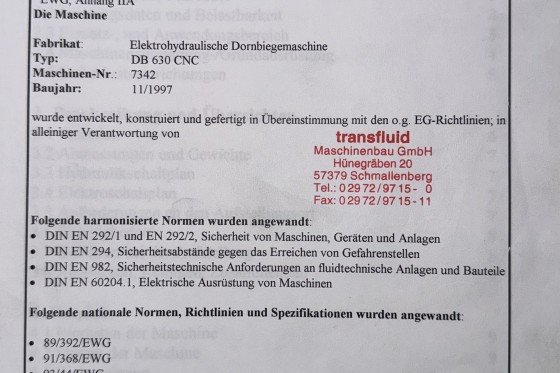

Pijpenbuigmachine Transfluid - DB 630 CNC

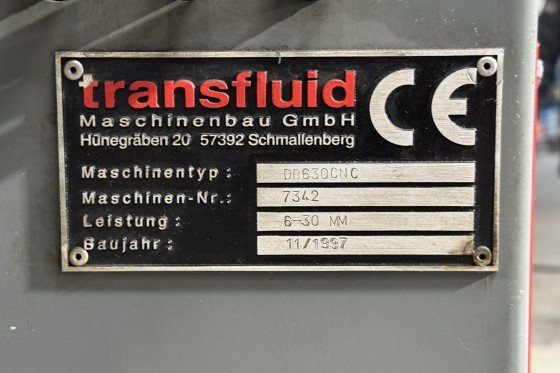

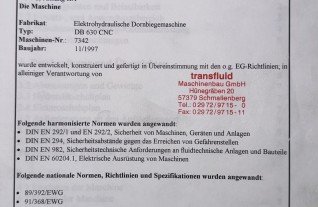

MACH-ID 8531| Merk: | Transfluid |

| Type: | DB 630 CNC |

| Besturing: | Transfluid |

| Bouwjaar: | 1997 |

Capacity:

| – Round tubing mild steel | 30 x 2,0 mm Ø |

| – Round tubing stainless steel | 30 x 1,5 mm Ø |

| – Square tubing mild steel | 20 x 2,5 mm |

| – Max. moment of resistance | 1,18 cm³ |

| – Bending angle up to | 180° + 10° spring back |

| – Bending speed | 65°/ Sec. |

| – Speed of front feed | 400 mm/sec. |

| – Speed of rotation | 90°/sec. |

| – Accuracy of the bending axis | +/-0,2° |

| – Accuracy of the length | +/-0,1 mm |

| – Accuracy of the rotation | +/-0,1° |

| – Arbor length/Usable length | 3048 mm |

| – Radii | max. 85 mm |

| – Bending height | 1050 mm |

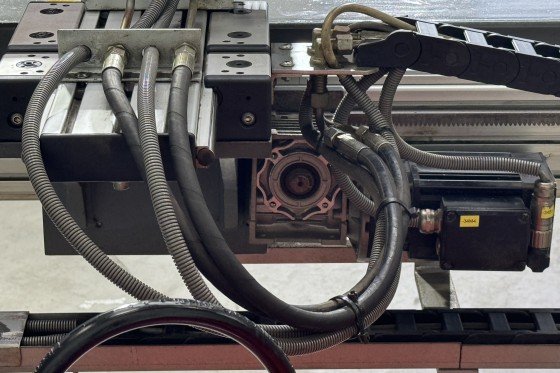

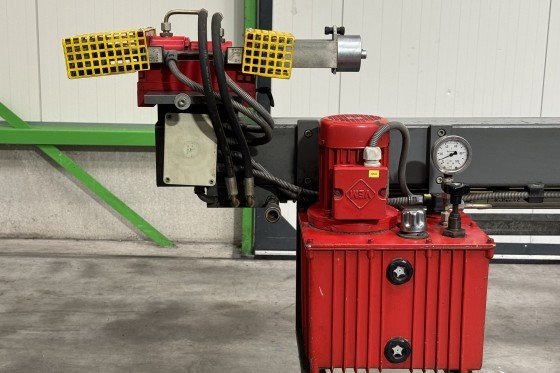

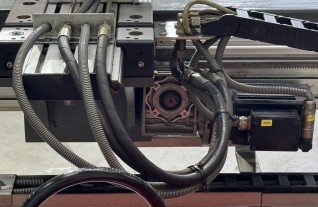

| – Power bending axis | electro-hydraulic |

| – Automatic positioning of the rotation and length | servo-electric |

| – All other axes (e.g. clamping, mandrel forwards/backwards, etc.) | electro-hydraulic |

Machine equipment-/basic accessories:

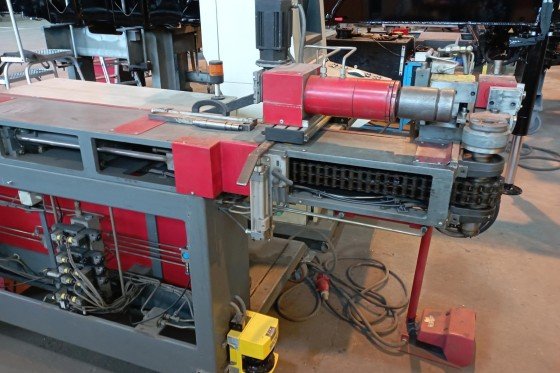

– Compact, exposed bending head

– Bending direction clockwise

– With hollow shaft for using tooling for small radii

– Include wide opening pressure die, to allow the off set bend device with the long neck clamping to move directly behind the bending tool

Attention: For each tube-Ø you need a separate collet

– For a correct positioning of the mandrel the machine is equipped with a mandrel support

– the machine is conform to the electric and mechanical security guidelines and the CE norm

– The emergency area in front of the machine is controlled via scanner

– Starting of operation via hand button

– With automatic tool resetting

– Manual operation

Each function clamping on/off, mandrel forward/back, bending on/off initiated by selection and pressing of respective button (for proto type and sample production)

– Standard-norm-hydraulic components

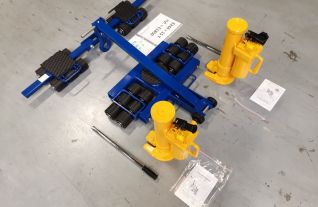

– Machine stationary

– Colour RAL 3020 red, 7047 grey

Machine data:

– Including connection for external pressured air supply, 6 bar

– Nominal pressure 250 bar, Operating pressure 150 bar

– Operating voltage 400 Volt – 50 Cyl. – 3 Ph. 22 KW

– control voltage: 24 VDC

– Capacity of the hydraulic tank 70 Ltr.

– Length 4700 mm

– Width 1400 mm

– Height 1500 mm

– Weight approx. 2400 kg + control panel 200 kg

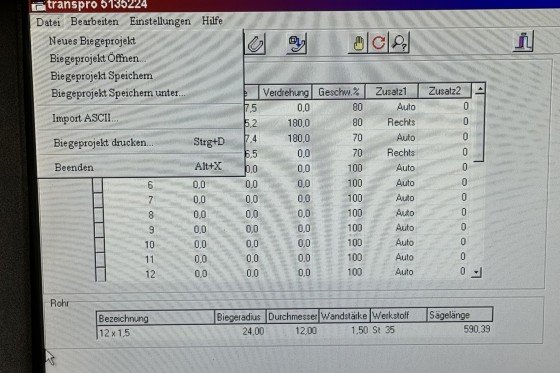

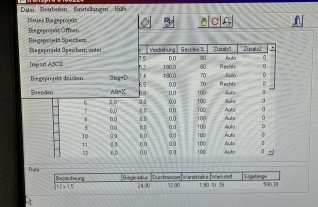

Control description:

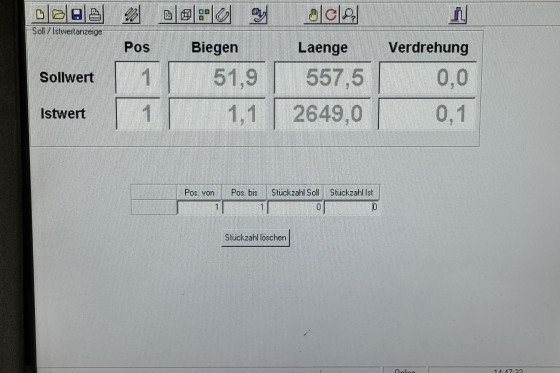

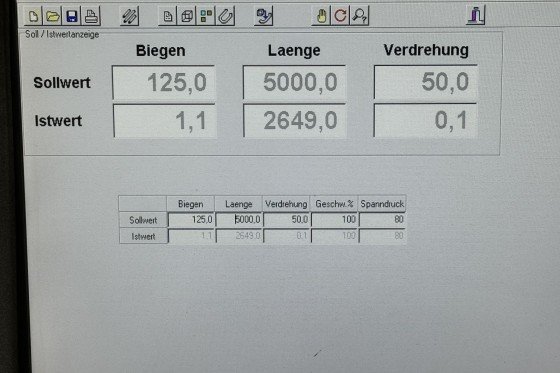

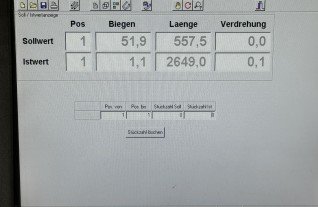

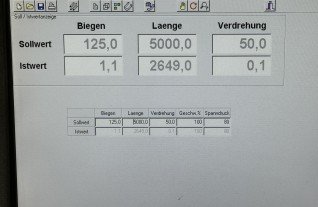

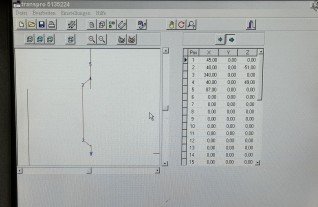

– Fitted with 3-axis control of the bending angle, the rotation axis and the longitudinal movement in the different planes

– The bending axis, the rotation axis and the length axis are coupled with each other, it ensues a permanent actual and nominal comparison also the control checks the tolerance and actuates further operations

– Integrated computer – IBM-compatible, current technology

– It ensues a permanent actual and nominal comparisation on the screen

– User surface Windows

– Separate control element including Tozchpanel for setup and start of automatic cycle

Standard equipment CNC control:

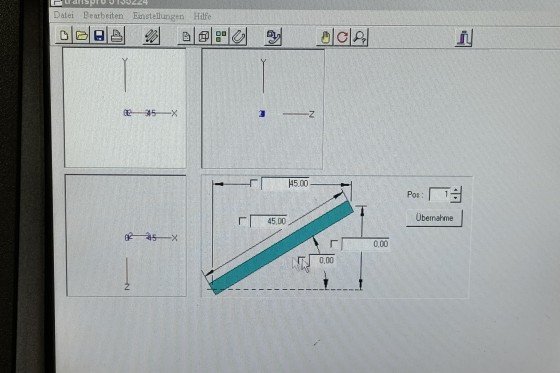

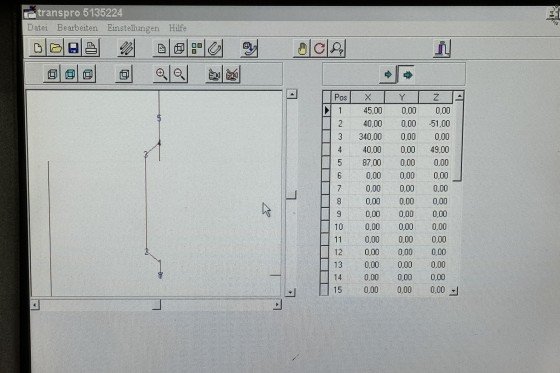

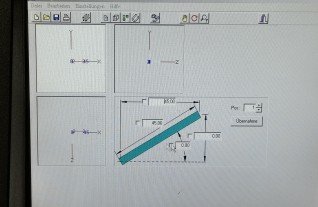

– With max. 20 different positions of each tube, all positions are controlled in the PC program

– Possibility to store 1 Mio. tubes with 20 positions each under drg. numbers

– After input you can store the tube

– Storage of the drg. numbers according to WIN Standard

– If the control registrates a breakwown or faults, you can see in the screen via text

– The off set bend device moves to the front position for an easy input and output of the tubes

Specificaties

Afmetingen (Schatting)

Belangrijk: De informatie op deze pagina is naar beste vermogen en overtuiging verkregen en waar nodig verkregen van de fabrikanten.De nauwkeurigheid kan niet worden gegarandeerd maar de informatie wordt te goeder trouw gegeven. Dienovereenkomstig vormt het geen vertegenwoordiging of contractuele voorwaarden.We raden u aan om alle essentiële details te controleren!

Recent bekeken machines

Terug naar overzicht