Deze machine is verkocht

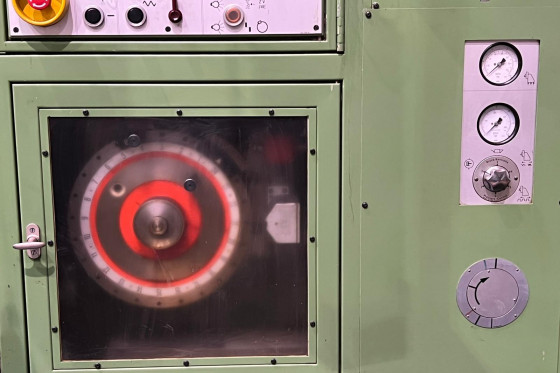

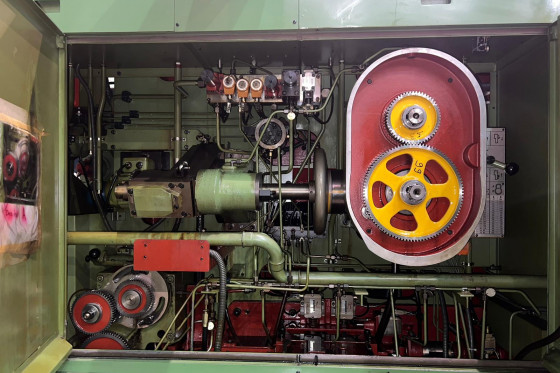

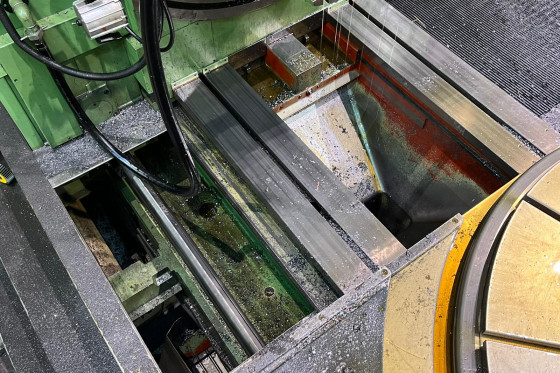

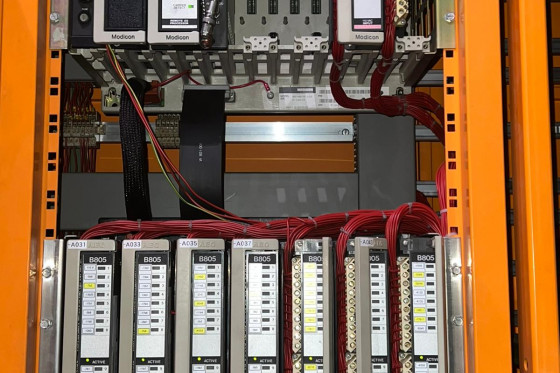

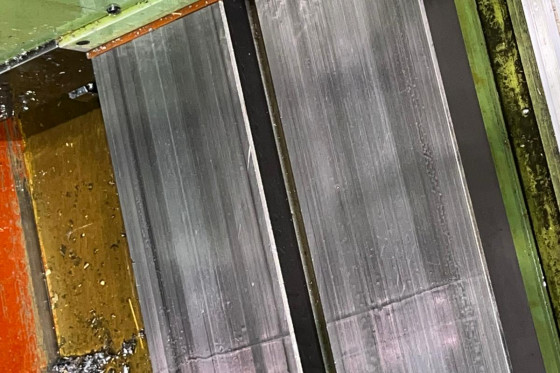

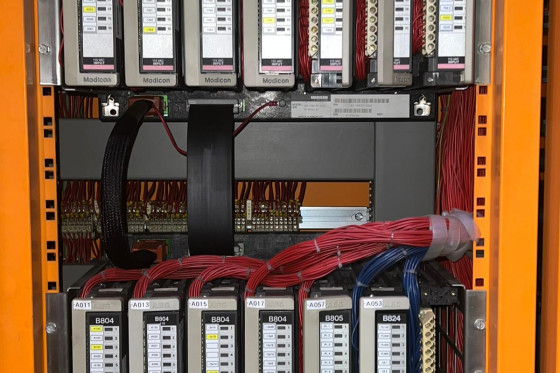

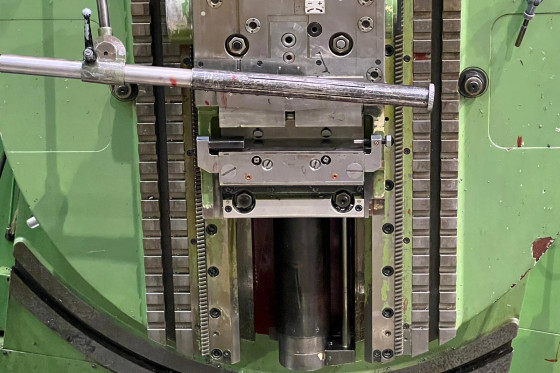

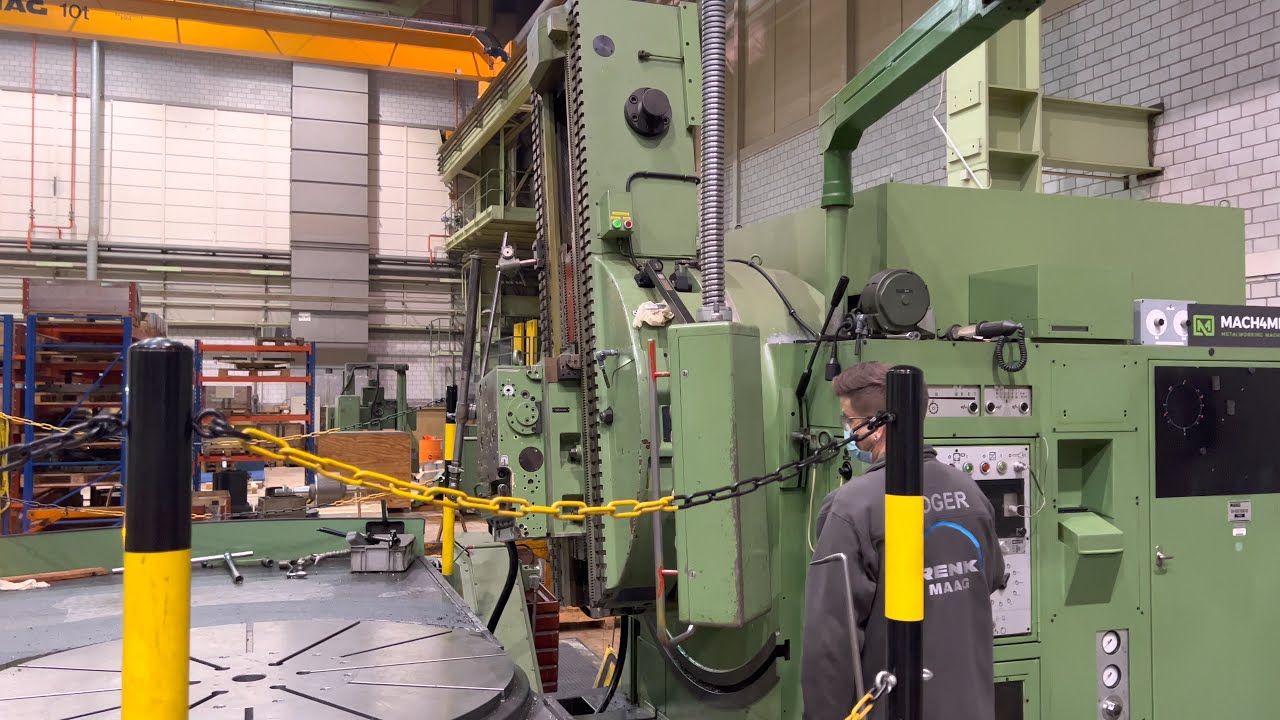

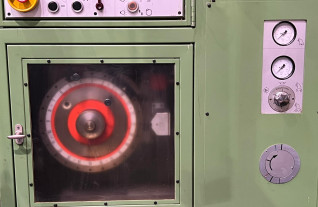

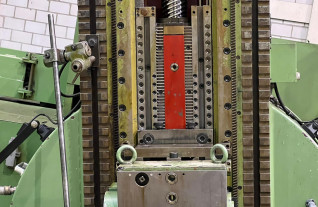

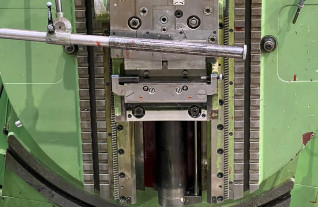

Tandwiel steekbank MAAG - SH-450

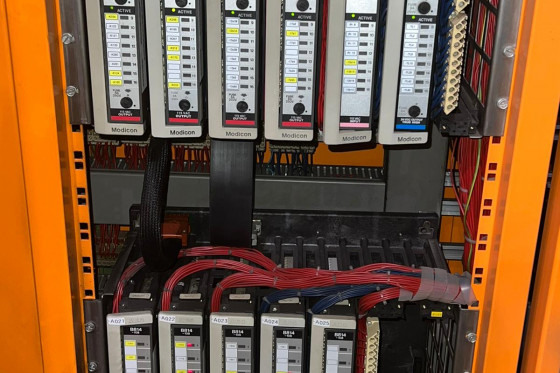

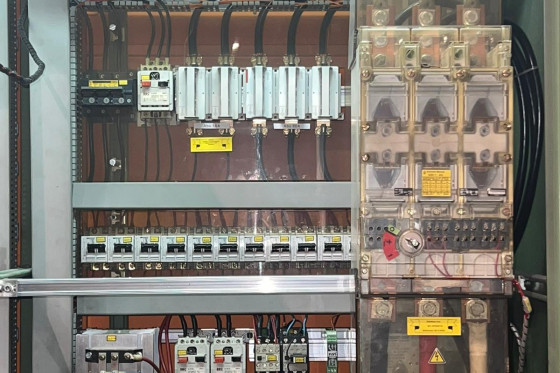

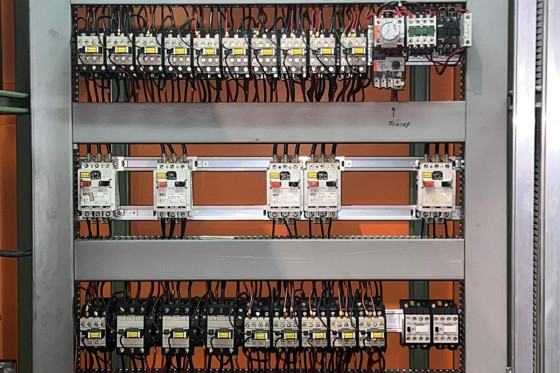

MAAG SH-450 Gear Shaper Ø 5000 MACH-ID 6897| Merk: | MAAG |

| Type: | SH-450 |

| Bouwjaar: | 1980 |

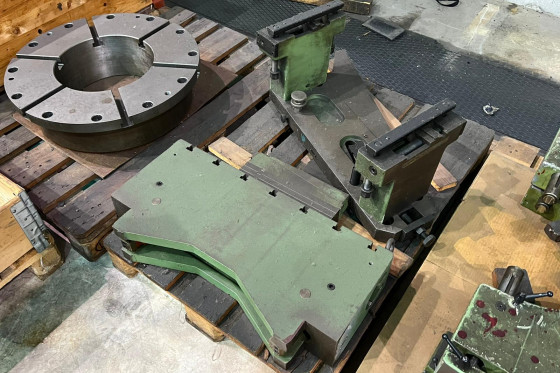

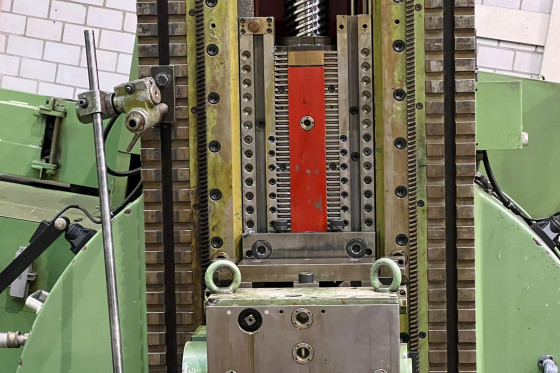

- Internal attachment

- Steady rest

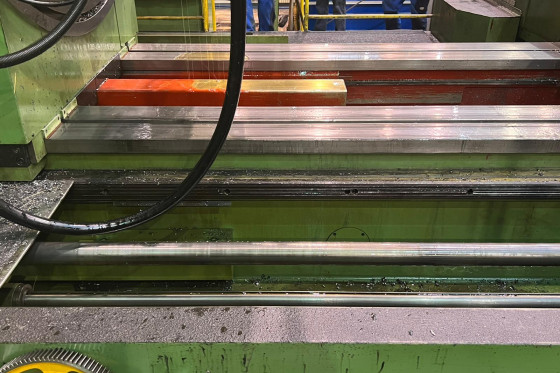

- Extended stroke to table 1700 mm

- Gear width up to 870 mm

- BIG package change gears

- BIG package cutting tools

Specificaties

Afmetingen (Schatting)

Belangrijk: De informatie op deze pagina is naar beste vermogen en overtuiging verkregen en waar nodig verkregen van de fabrikanten.De nauwkeurigheid kan niet worden gegarandeerd maar de informatie wordt te goeder trouw gegeven. Dienovereenkomstig vormt het geen vertegenwoordiging of contractuele voorwaarden.We raden u aan om alle essentiële details te controleren!

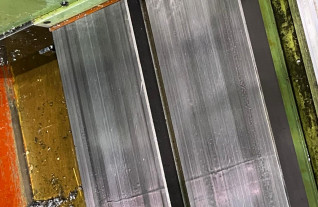

- External gears

- Internal gears

- Herringbone gears

- Double helical gears

- Gear racks.

Recent bekeken machines

Terug naar overzicht